FM200 Gas Fire Suppression System

Areas of high value with limited space such as computer rooms

Home / Automatic Fire Fighting / Gas Fire Suppression Systems / Inert Gas Fire Suppression System

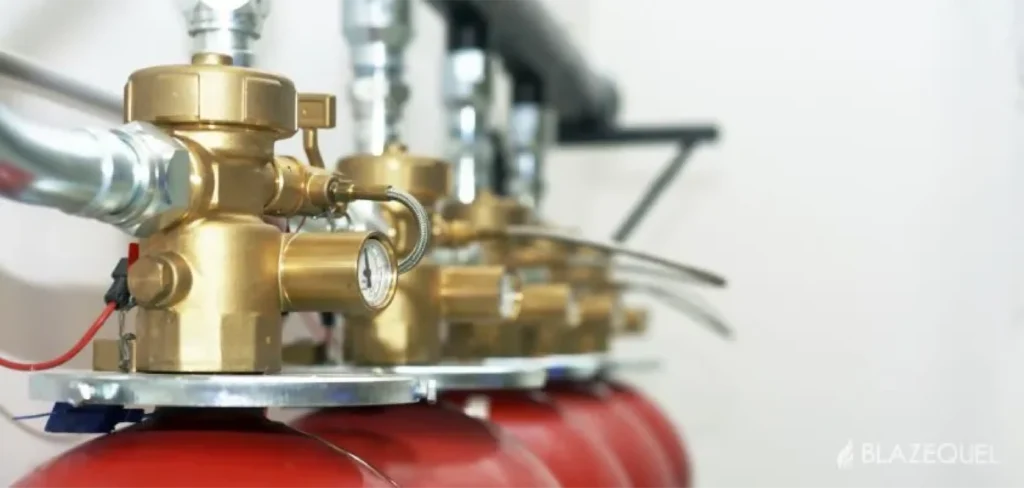

Inert gas suppression systems such as CO2 or Argon or Inergen are commonly used in suppression systems. These are unlikely to be affected by the environmental concerns which are often raised in connection with the active gases. The disadvantage of them is that more gas is needed to suppress the fire, consequently needing larger cylinders, more actuation gear and of course consideration of the weight bearing of the cylinders, as well as their size.

Contact us now to learn more about Blazequel inert gas fire suppression and how they can be an essential part of your fire safety plan.

Inert gas suppression systems work by discharging a mixture of inert gases, such as nitrogen and argon, into the protected space. The gases displace oxygen, reducing its concentration below the level required for combustion.

Common inert gases used in suppression systems include nitrogen, argon, and blends of these gases. The choice of gas depends on factors such as the type of fire risk, the sizer of the protected area, and environmental considerations.

Inert gas suppression systems are suitable for suppressing fires involving Class A, B, and C hazards. They are effective for extinguishing fires in areas with sensitive equipment and materials that may be damaged by water, such as data centres, archives, and control rooms.

Inert gases are generally considered safe for occupied spaces because they do not leave any residue, are electrically non-conductive, and do not deplete the ozone layer. However, the reduced oxygen levels during discharge may pose a risk to human health, so proper system design and evacuation procedures are essential.

The concentration of inert gas required for effective fire suppression is typically determined based on the type of hazard and the protected space’s volume. Engineers use calculations to establish the appropriate design concentration to ensure the fire is extinguished while minimizing the risk to occupants.

The discharge time for inert gas systems is usually rapid, typically within a few minutes. Quick discharge is crucial for suppressing the fire before it can spread further.

Inert gas suppression systems are often used as standalone systems, but they can also be integrated with other fire protection methods, such as sprinklers or water mist systems, to provide a comprehensive fire protection strategy.

Inert gases themselves are generally environmentally friendly. However, the production and transportation of these gases may have associated environmental impacts. Additionally, the potential release of stored inert gases during a discharge event should be carefully considered.

Regular inspections and maintenance are essential to ensure the reliable performance of inert gas suppression systems. Maintenance schedules should adhere to local regulations and standards, and inspections may include checks on pressure levels, leak detection, and system functionality.

Different regions may have specific standards and regulations governing the design, installation, and maintenance of inert gas suppression systems. Common standards include NFPA 2001 (National Fire Protection Association) and ISO 14520. Compliance with local regulations is crucial for ensuring the system’s effectiveness and safety.

Don’t hesitate to reach out to us, or you can easily fill out the form below. We’re here to assist you.

Areas of high value with limited space such as computer rooms

Protect smaller areas; Suitable for protecting electrical switchgear, servers, and plant applications.

Protect smaller areas; Suitable for protecting electrical switchgear, servers, and plant applications.