Inert Gas Fire Suppression System

Suitable for large spaces such as control rooms and manned areas

HFC 227 EA (commonly known as FM200) is a safe, clean, and electrically nonconductive agent.

Gas suppression systems come in two different types.

There are inert gases, such as Inergen or CO2. Or there are active gases, such as FM200, FE36 and Novec 1230. These gases have the advantage that they actually chemically fight the fire as well as just smothering it, so consequently a lesser concentration of gas is required to extinguish a fire. This means that smaller cylinders would be required and usually a quicker means of attacking the fire. Consideration does have to be made that the use of these gases is an environmental concern and other gases that have been used in the past have already been banned.

Contact us now to learn more about Blazequel FM200 fire suppression and how they can be an essential part of your fire safety plan.

FM200 is a colourless, odourless, and electrically non-conductive gas that is used as a fire suppressant. It is part of the family of halocarbon agents and is known for its fast response time and effectiveness in suppressing fires.

FM200 works by interrupting the combustion process. It absorbs heat and reduces the oxygen concentration in the protected space, thereby suppressing the fire. It is effective in extinguishing fires without causing damage to sensitive electronic equipment or leaving a residue.

FM200 is primarily designed for Class A, B, and C fires. Class A fires involve ordinary combustibles, Class B fires involve flammable liquids, and Class C fires involve electrical equipment. FM200 is not suitable for certain metal fires (Class D).

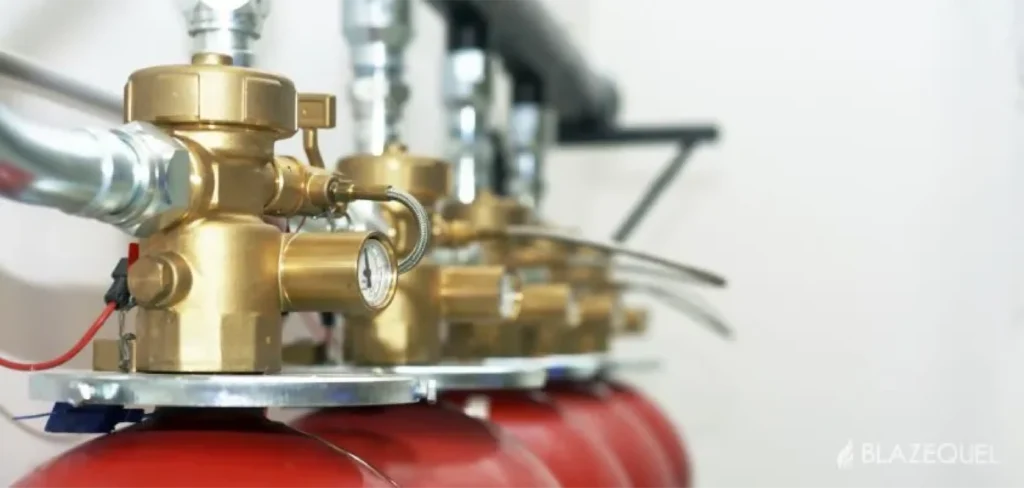

FM200 is stored as a liquid in pressurized cylinders. When a fire is detected, the system releases the FM200 into the protected area. The discharge can be achieved through a network of pipes and nozzles strategically placed in the protected space.

Yes, FM200 is considered safe for use in occupied spaces when applied within specified design concentrations. The concentration levels are carefully calculated to be effective in suppressing fires while ensuring the safety of people in the protected area.

FM200 is considered an environmentally friendly fire suppression agent compared to some older alternatives. It has a low ozone depletion potential (ODP) and a short atmospheric lifetime. However, it is still essential to follow proper handling and disposal procedures.

FM200 is known for its rapid response time. It can extinguish a fire in a matter of seconds, which is crucial for protecting sensitive electronic equipment and minimizing potential damage.

Regular maintenance and inspection are essential to ensure the reliability of FM200 systems. This includes checking pressure levels in cylinders, inspecting valves and nozzles, and ensuring that the detection and control systems are in proper working condition.

The installation and use of FM200 systems are subject to various local and international regulations and standards. These may include guidelines from organizations like NFPA (National Fire Protection Association) and ISO (International Organization for Standardization).

While FM200 is suitable for a wide range of applications, it’s important to consider factors such as room volume, temperature, and ventilation when designing a system. Professional engineers typically conduct a thorough analysis to ensure the system’s effectiveness in a specific environment.

Don’t hesitate to reach out to us, or you can easily fill out the form below. We’re here to assist you.

Suitable for large spaces such as control rooms and manned areas

Protect smaller areas; Suitable for protecting electrical switchgear, servers, and plant applications.

Protect smaller areas; Suitable for protecting electrical switchgear, servers, and plant applications.